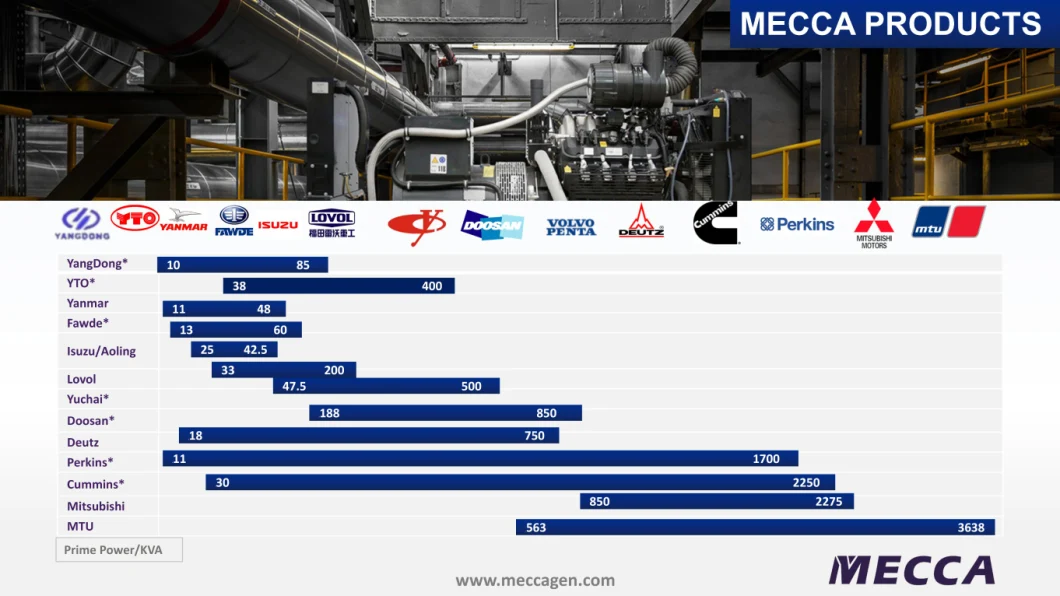

100kVA-2500kVA 3 Phase Silent Electric Generac Diesel Power Generator with Yuchai Mitsubishi Sme FAW Sdec Yto Weichai Yangdong Chinese Engine for Sale

MECCA POWER MEI 2020 REWARDED Low Fuel Consumption DIESEL GENERATORAll key part produced by Chinese manufacturers,design

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | MC |

| Output Type | AC Three Phase |

| Speed | Low Speed |

| Conditions of Use | Land Use |

| Usage | Common Units, Standby Unit, Emergency Crew |

| Landuse Type of Unit | Automation Type |

| Excitation Mode | Static Exciter |

| Engine Brand | Yuchai FAW Sdec Yto Weichai Yangdong |

| Alternator | Stamford / Leroy Somer /Mecc Alte |

| Control Panel | Smartgen,Deepsea,Optional |

| Soundless Generator Price | Three Phase Generator Price |

| Canopy Type | Silent Sound Proof/Weather Proof/Anti-Rusted Proof |

| Frequency(Hz) | 50Hz/60Hz ,1500rpm 1800rpm |

| Voltage Output | 230/400V,22-480V |

| Application[a] | Telecom/Mining/Construction/Data Center |

| Application[B] | Commercial/Power Plant/Factory/Industrial |

| Accessory | Spare Parts Documents |

| Governing Type | Mech/Elec/ECU/Ecm/Adec/Hpcr |

| Electric Start Generator | Portable Power Generator Set |

| Certificate Available | CE, ISO, OEM Authorization etc. |

| AC Three Phase Diesel Generators | Power Generating Unit |

| Low Rpm Permanent Magnet Generator | Diesel Electrical Set |

| Transport Package | Both Standard Marine Packing or Compact Packing. |

| Specification | As below Spec. with details |

| Trademark | Mecca |

| Origin | China |

| HS Code | 85021100 |

| Production Capacity | 1000/Year |

Product Description

MECCA POWER MEI 2020 REWARDED Low Fuel Consumption DIESEL GENERATORAll key part produced by Chinese manufacturers,designed by Mecca,Fuel consumption down to 4.28L/h,with superior sound proof tech,61-63 dB in 7m.We're Mecca Power,but do more than power,always trying best to supply performance monster to you.

| Alternator Data | ||||||||||||||||||

| ♦ Operate either 50Hz or 60Hz. | ♦Stator grease insulation covered | |||||||||||||||||

| ♦ Standard enclosure IP23, but IP44, IP55 for option | ♦Rotator and excitation high polymer | |||||||||||||||||

| ♦ Insulation class H. | ♦ Resist the corruption oil and acid | |||||||||||||||||

| ♦ Shunt excitataion systems. | ♦Rotator balance is in accordance with BS5625 | |||||||||||||||||

| ♦ AREP or PMG system for options. | standard 12.5 | |||||||||||||||||

| ♦ Automatic voltage regulator | ♦High-quality lubrication sealed long-time bearing | |||||||||||||||||

| ♦ Single bearing alternator | ♦Rotator silicon steel close tight | |||||||||||||||||

| Standard Accessories | ||||||||||||||||||

| *Auto Control Panel | *Starting Motor | |||||||||||||||||

| *Main Ciruit Breaker | *Exhaust silencer | |||||||||||||||||

| *Fuel tank | *Starting battery | |||||||||||||||||

| *Base Frame | *Float battery charger | |||||||||||||||||

| *Filter | *Flange | |||||||||||||||||

-----------------------------------------------------------------------------------------------MAINTENANCE---------------------------------------------------------------------------------------------

General Troubleshooting This section lists the generating set for some common fault, the reasons for the failure and determines the method of fault. General operators can determine their own fault and note, maintenance it according to the brochure. But please contact the repairing agents when meeting a special note or not listed failure of operation. Please remember the following suggestions before repairing: - Make sure that study the failure carefully before any operation. - Repair with the easiest way and most commonly used method. - Find the exact causes of failure and completely solve the fault. 1. Generator Sets Description of this section is for reference only. If the following failure occurs please contact the repairing agents. (Some models of control panel installed only parts of the following warning indicator light)

| Icon | Indicator Light | Reason | Fault Analysis |

| Low oil pressurealarm | Low oil pressurealarm | When oil pressure does notreduce normally, the light is on. | -General because of a lack of oil or lubricationsystem failure caused by (refueling or replacingthe oil filter)-When occurs this fault should automaticallyshutdown generator sets immediately. |

| High watertemperaturealarm | High watertemperaturealarm | When the water temperaturehas risen to a level higher thanor equal to the sensor setting,the light is on. | -General because of a lack of water or oilshortage, or overload.-When occurs this fault should automaticallyshutdown generator sets immediately. |

| Low fuel levelalarm | Low fuel levelalarm | When a fuel level has beendetected by the sensor fitted tothe daily tank, the light is on. | -General because of a lack of water or oilshortage, or overload.-When occurs this fault should automaticallyshutdown generator sets immediately. |

| Battery chargerfault alarm | Battery chargerfault alarm | If the charging system has fault,when engine running, the light isoff. | -Battery charging system fault caused.-The light is on at the initial start, when thecharger reaches a certain speed, the light is off.-This failure will not lead to automatic shutdowngenerating units. |

| Crank failurealarm | Crank failurealarm | When the generator set failedthree times (or six times) in arow starting, the light is on. | -Oil supply system or re-start the system failurecaused. |

| Overload orbreaker trippingalarm | Overload orbreaker trippingalarm | When overloading or Shortcircuit, the light is on. Trippingcircuit breakers cause generatorset load out. | -In this fault, it need to load or unload some partsto eliminate short-circuit, and then re-close thecircuit breaker. |

Introduction of Maintenance grade(Interval) for the generator set A Level Maintenance Interval (Daily Maintenance)1. Check Daily Report of Genset .2. Check fuel level and coolant level. 3. Check alternator for cracks or other damage, and the condition of the belts must be checked, flab or other damage.4. Check the Air filter. The air filter should be replaced when necessary .5. Release fuel tank and fuel filter's water and sediment.6. Check the water cooling filter.7. Check starting battery and electrolyte, add electrolyte when necessary. 8. Check the starter, check noisy defect.9. Use air syringe cleaner to clean the water tank, coolant system and cooled fin net.B Level Maintenance Interval (Less than 400 hours)1. Repeatedly check A Level Daily Maintenance steps.2. After operating 100 to 250 hours, replace the fuel filter. All the fuel filters should not be cleaned, it should be replaced. 100 to 250 hours is just flexible time, actually it must be according to the practice and real fact. 3. After operating 200 to 250 hours, replace the oil & oil filter. All the lube oil must fit up to the CF Grade of American Petroleum Institute.4. After operating 300 to 400 hours, replace the air filter. The air filter can be cleaned with air syringe, or it can be replaced. The replacement must be according to the environment and real fact.5. Replace the cooling system and add coolant concentration.6. Clean the crankshaft and inlet, outlet air- filter net. C Level Maintenance Interval (2000-3000 hours), Please do as follows:1. Repeatedly check A and B Level Daily Maintenance steps.2. Remove the tap of valve, clean and wash oil dirt and sludge.3. Fasten snails from each part (including running parts and fixed parts)4. Clean and wash the crankcase, oil sludge, steel scraps and sediment with engine.5. Check wearing of the engine turbo, clean and wash accumulation of carbon, adjust it when necessary.6. Check and adjust valve clearance.7. Check PT pump, quality of injection, adjust injection process, adjust it when necessary.8. Check and adjust the tension of fan belt and water pump belt, adjust and replace it when necessary; clean and wash water tank radiator fins, then check the using capability of thermostat.Current Repair (D Level Maintenance)(3000-4000 hours)1. Check valve, valve seat and other wearing, repair or change it when necessary.2. Check P pump, quality of injection, repair and adjust it when necessary.3. Check and adjust connecting rod and fastening twisting torque.4. Check and adjust valve clearance.5. Check the trip of injector.6. Check and adjust tension of fan and generating belt.7. Clean and wash accumulation of carbon in inlet pipes.8. Clean and wash the core of air cooler.9. Clean and wash the whole oil lubrication system.10. Clean and wash room of rocker arm, oil sludge in the sump and Metal scrap-iron.Medium Repair (6000-8000 hours)1. Including the items of minor repair.2. Disassemble generator(except crankshaft)3. Check the easy worn spare parts in pitman shaft system, gas distribution system, lubrication system, cooling system of cylinder, Piston, Intake and exhaust valve, replace them when necessary.4. Check fuel supplying system, adjust oil pump and injector.5. Repair and test the alternator, clean oil-sediment and lubricate the bearing of alternator.Overhaul (9000-15000hours)1. Including the items of intermediate repair.2. Disassemble all the parts in the generator.3. Replace cylinder, piston, piston loop, big and small bearing bushes, trusting pad of crankshaft, intake and exhaust valve, a whole set of tools for generator repair 4. Adjust oil pump, injector and replace pump core, injector5. Replace a whole set of repair tools for turbo charger and a repair set for water pump.6. Adjust the parts of connecting rod, crankshaft and generator body,repair or replace them when necessary

Related Products